News form igus

Award ID: 1133 Company: SONET PLUS D.O.O.

igu-award-adm | Februar 16, 2021

Allgemeine Informationen

- Datum: 2021-02-16 11:13:25

- Firma: SONET PLUS D.O.O.

- Ansprechpartner: Mr Bojan Zorič

- E-Mail: bojan.zoric@sonetplus.si

- Anschrift: SENIČICA 5C, SI-1215 MEDVODE

- Telefon: 041 936 221

- Land: Slovenija

- Awareness: Colleagues

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Welche Anforderungen mussten die Lager erfüllen?

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Bilder

Award ID: 1132 Company: SUPERWURM e.K.

igu-award-adm | Februar 16, 2021

Allgemeine Informationen

- Datum: 2021-02-16 07:11:01

- Firma: SUPERWURM e.K.

- Ansprechpartner: Herr Martin Langhoff

- E-Mail: martin.langhoff@superwurm.de

- Anschrift: Felix-Wankel-Str. 8, 52351 Düren

- Telefon: 02421/2085955

- Land: Deutschland

- Awareness: Suchmaschinen

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

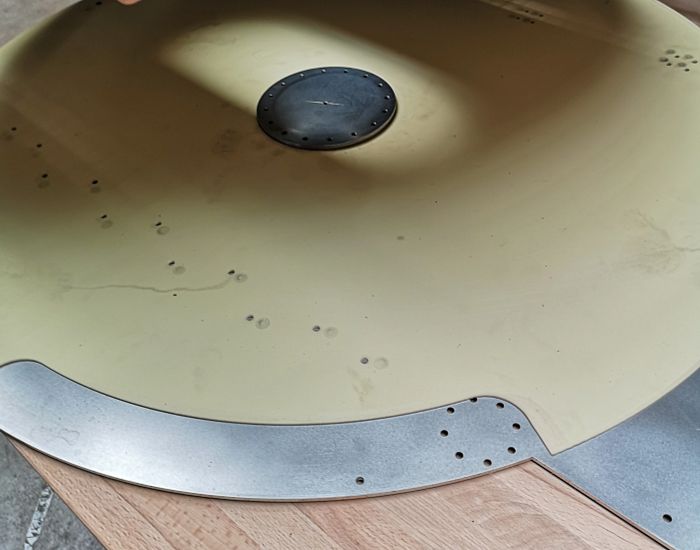

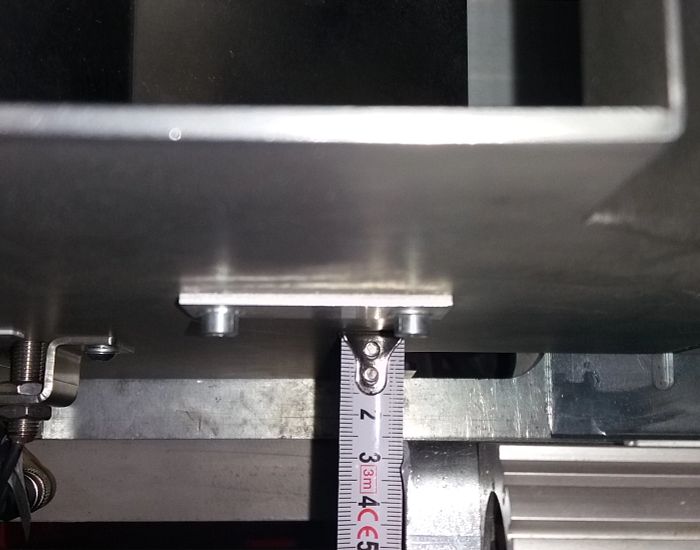

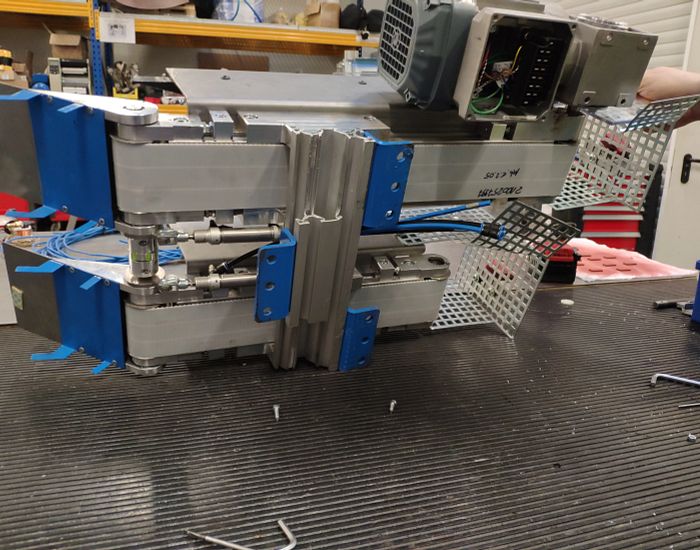

Der Drehteller muss sehr flach sein, damit sich der Rollwagen leicht in die Anlage schieben lässt (flache Rampe) und Staub darf kein grundsätzliches Problem darstellen.

Welche Anforderungen mussten die Lager erfüllen?

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Bilder

Video

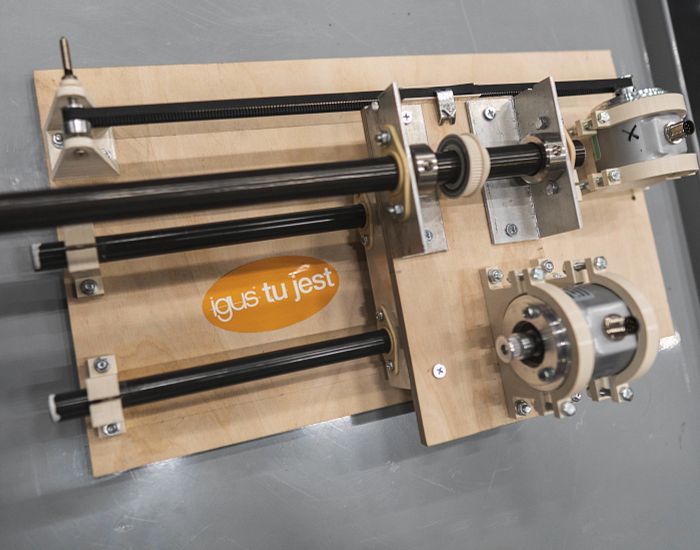

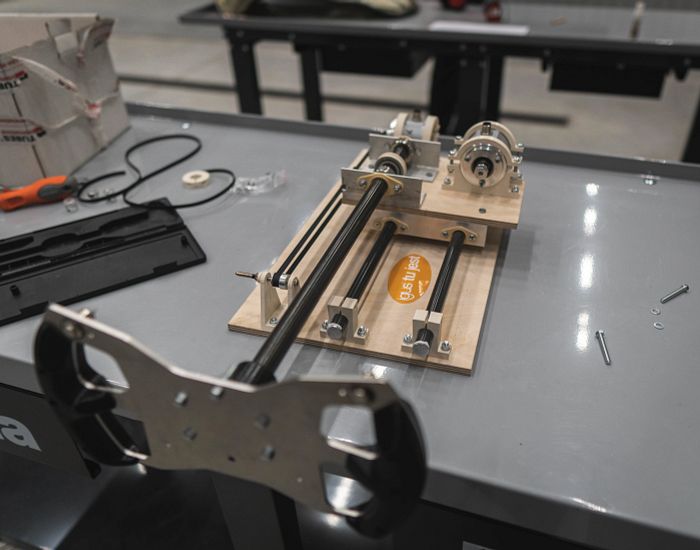

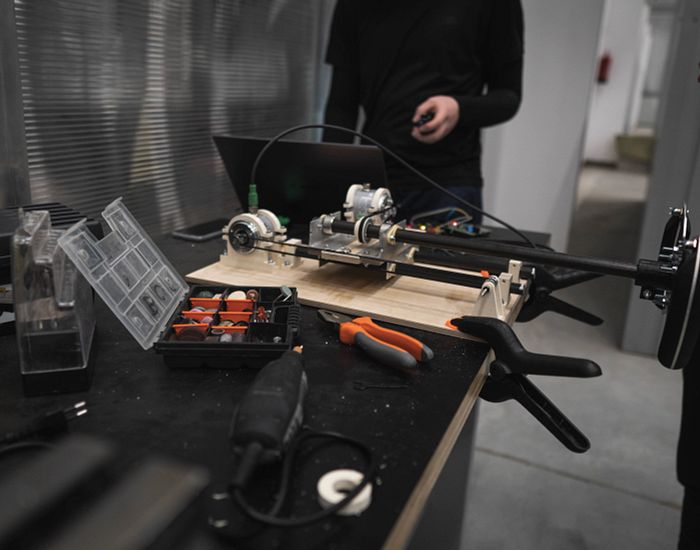

Award ID: 1131 Company: Prywatnie / privat

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 23:00:23

- Firma: Prywatnie / privat

- Ansprechpartner: Pan Bartłomiej Lachowicz

- E-Mail: Bartulach@outlook.com

- Anschrift: Partyzantów, 5b, 58 Szklarska Poręba

- Telefon: 663486582

- Land: Polska

- Awareness: Colleagues

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Welche Anforderungen mussten die Lager erfüllen?

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Video

Video

Award ID: 1130 Company: Thiessen Tillage Equipment

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 22:59:24

- Firma: Thiessen Tillage Equipment

- Ansprechpartner: Mr Ryan Thiessen

- E-Mail: ryan@thiessentillage.com

- Anschrift: 1167 Lakeshore Road West, L2R 6P9 St. Catharines

- Telefon: 9053592210

- Land: Canada

- Awareness: Other

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

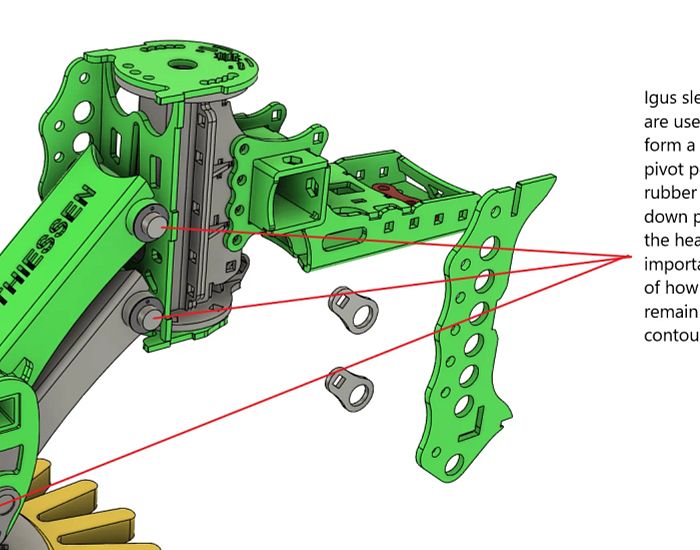

Two main challenges we wanted to overcome were low speed, but interrupted, radial loading of the bearings, as well as lack of maintenance in terms of timely greasing.

Welche Anforderungen mussten die Lager erfüllen?

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

We have also started evaluating some of the plate stock options for some of our other products that use hydraulic sliding motion as a way to reduce the need for greasing, which is often neglected or overlooked in the busy agricultural industry.

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

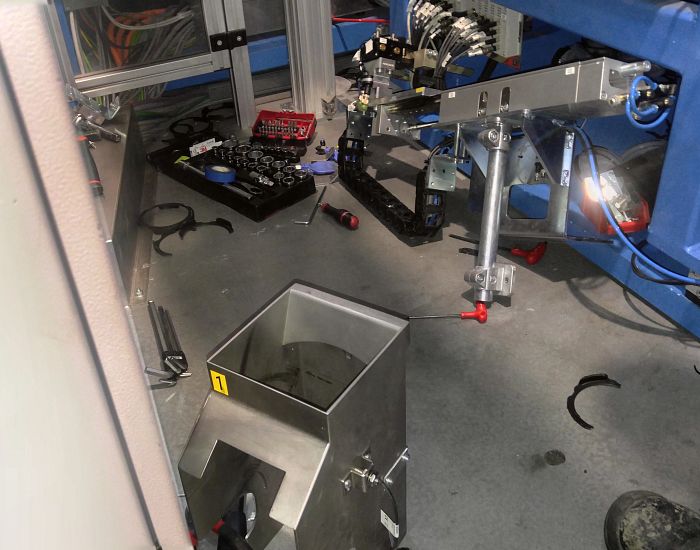

Bilder

Video

Award ID: 1129 Company: ControlTec

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 22:59:12

- Firma: ControlTec

- Ansprechpartner: Pan Mariusz Trekiel

- E-Mail: mariusz.trekiel@controltec.com.pl

- Anschrift: Tarnogajska 11-13, 50-512 Wrocław

- Telefon: 572725256

- Land: Polska

- Awareness: e-mailing

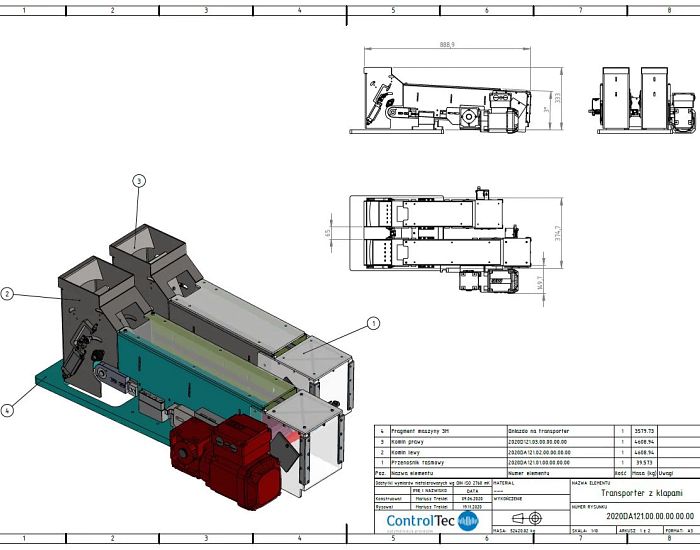

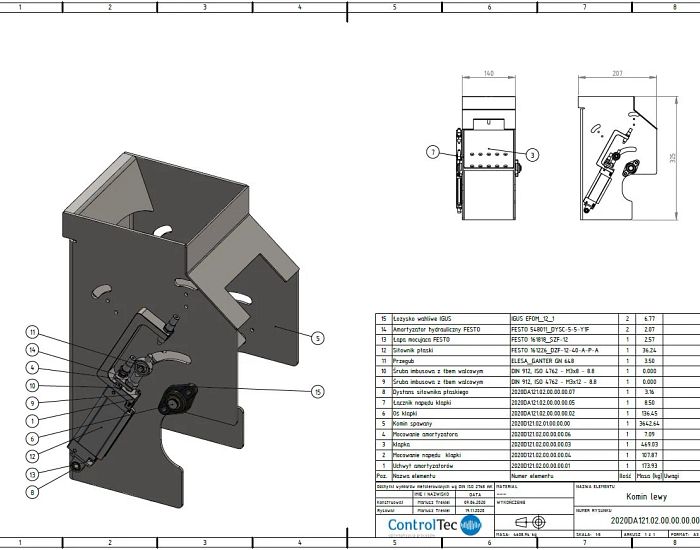

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

I guess the old design has had the axis of rotation of NOK/OK flaps on common shaft with a belt drive due to extremely lack of space in other place. Another prablem with the old design, it was necessary to remove flaps during belt exchange. It takes at least 1 day for 2 maitenance staff because of adjustment the machine sensors after that, which are extremaly sensitive to misaligment. When you realise that it is needed to change belt alt least twice a year and there are 5 the same assembly lines in the factory factory, its obvious that is waste of time and money! It is hard to describe without a picture but I am going to attatch a photo in next step.

Welche Anforderungen mussten die Lager erfüllen?

-compact design because of little space of installation

-no grease or other lubricant because produced parts are used for paintings

-extremely wear resistan because the machine operates 24/7

-compensate misaligment because it is needed to install on bended and welded housing

-reasonable price

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Now customer is happy because Overall Equipment Effectiveness (OEE) has grown significantly and maintenance personnel have less duties with this machine. Well done IGUS!

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

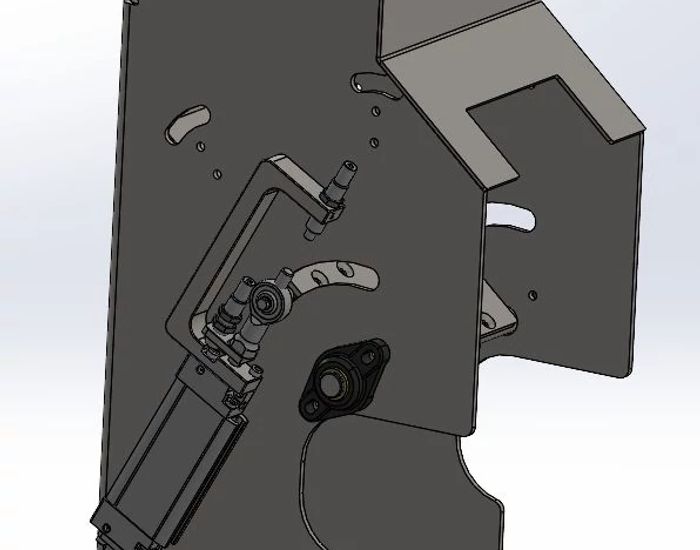

Bilder

Award ID: 1128 Company: BKF Myjnie Bezdotykowe Sp. z.o.o.

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 22:59:09

- Firma: BKF Myjnie Bezdotykowe Sp. z.o.o.

- Ansprechpartner: Pan Mariusz Kowalczyk

- E-Mail: m.kowalczyk@bkf.pl

- Anschrift: Skarbimierzyce 22, 72-002 Dołuje

- Telefon: 91 814 71 05

- Land: Polska

- Awareness: e-mailing

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Welche Anforderungen mussten die Lager erfüllen?

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Bilder

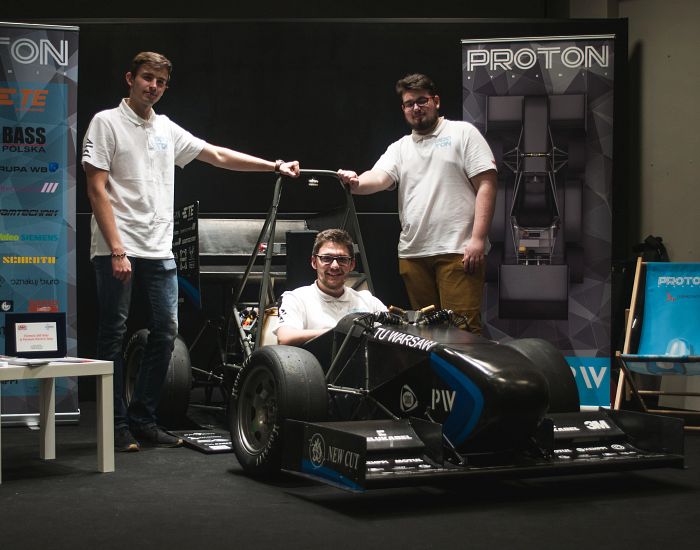

Award ID: 1127 Company: Politechnika Warszawska, Wydział Samochodów i Maszyn Roboczych, Koło Naukowe Proton Dynamic

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 22:23:15

- Firma: Politechnika Warszawska, Wydział Samochodów i Maszyn Roboczych, Koło Naukowe Proton Dynamic

- Ansprechpartner: Pan Daniel Chrościcki

- E-Mail: danielch.protondynamic@gmail.com

- Anschrift: Narbutta 84, 02-524 Warszawa

- Telefon: 603097859

- Land: Polska

- Awareness: Colleagues

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

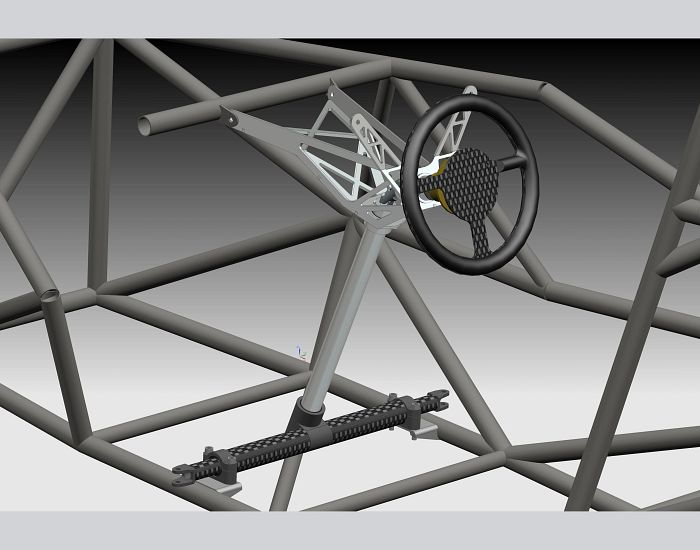

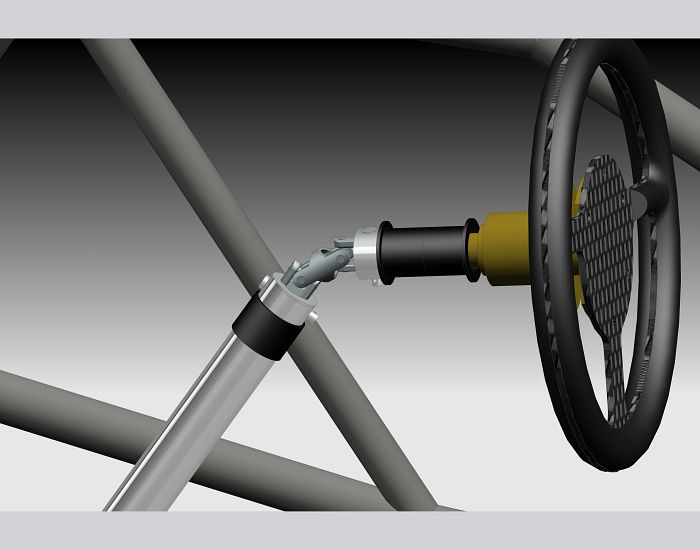

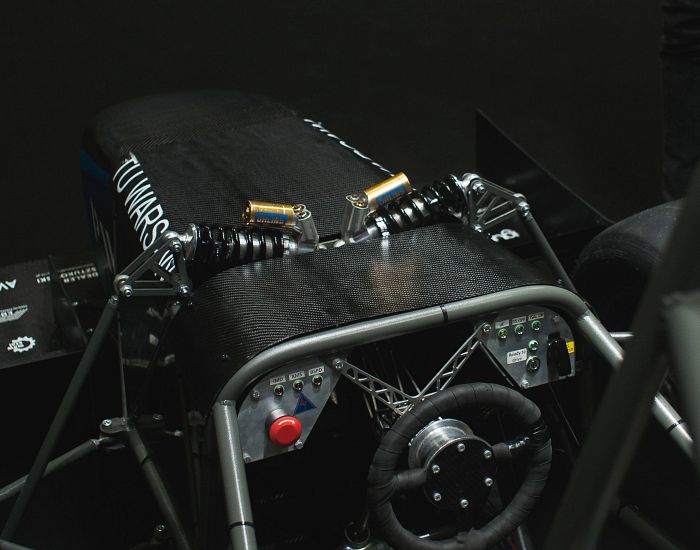

Formula Student is a competition series organized by Formula SAE International. Students from the worlds top universities compete in races held at famous circuits such as Silverstone and the Red Bull Ring. The task for the teams taking part in the competition is to design and build a race car. At the same time, students are also responsible for the finances, marketing, PR and logistics of the project. This initiative gives them the opportunity to put into practice the knowledge they have gained during their studies and work in a real business environment, with a limited budget and time. Formula student cars are designed according to a stringent, nearly 150-page technical regulation. To perform well on the track, the vehicles design should be as light and rigid as possible. At the same time, it must also meet stringent safety requirements. The basic parameters of the electric FSAE car: Wheelbase: 1525 mm Weight (without driver): 240kg Power (limited by regulations): 80kW, 107 KM Torque: 230 Nm Range on a single charge at race pace: approximately 35km Aerodynamic downforce at 100km/h: 2120N Designed using iglidur® plain bearings, the cars steering system is one of the key subsystems in terms of vehicle handling, as any imperfection in the steering system translates directly into a deterioration in the cars handling. A well-designed steering system needs to be strong while being as light as possible. These two qualities ensure good performance and a good feel for the car.

To meet these requirements, our team decided to build this subsystem entirely based on our proprietary solutions. The system consists of our proprietary carbon fiber composite steering wheel, from which the drive is transferred to the steering gear via a double cardan shaft. The seemingly simple design of the steering gear was turned upside down by our team. To make this component we used world class materials and technologies. All aluminum elements were CNC machined from high strength 7075 alloy and then surface hardened. Spatial structure is made of carbon-epoxy composite tubes, made with prepreg winding method with high modulus fibers, which are connected to the rest of the structure with the use of modern structural adhesives. The effort has definitely paid off. The whole system, although capable of transmitting 50Nm of torque (10 times more than is used for driving in a passenger car), weighs only 2150 grams. This is about the weight of the steering wheel alone in an average car. We are particularly proud of our own steering pinion, whose weight of 1200 grams beats all dedicated market solutions. All this would not be possible if it were not for the use of Igus polymer plain bearings.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Welche Anforderungen mussten die Lager erfüllen?

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

For the steering assembly, bronze bushings were used as an alternative to polymer bearings. Both solutions were tested by us in conditions simulating real operating conditions. The steering wheel was lubricated and covered with a layer of dust from brake pads. The tests showed significantly less wear on the carbon tubing on which the bearings ran when Iglidur® X polymer bearings were used.

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Bilder

Award ID: 1126 Company: Nortech Engineering Solutions S de RL de CV

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 22:10:31

- Firma: Nortech Engineering Solutions S de RL de CV

- Ansprechpartner: Mr Ruben Oviedo

- E-Mail: roviedo@ntmexico.mx

- Anschrift: Ramon Corral #27, 83010 Hermosillo

- Telefon: 6621000415

- Land: Mexico

- Awareness: Colleagues

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

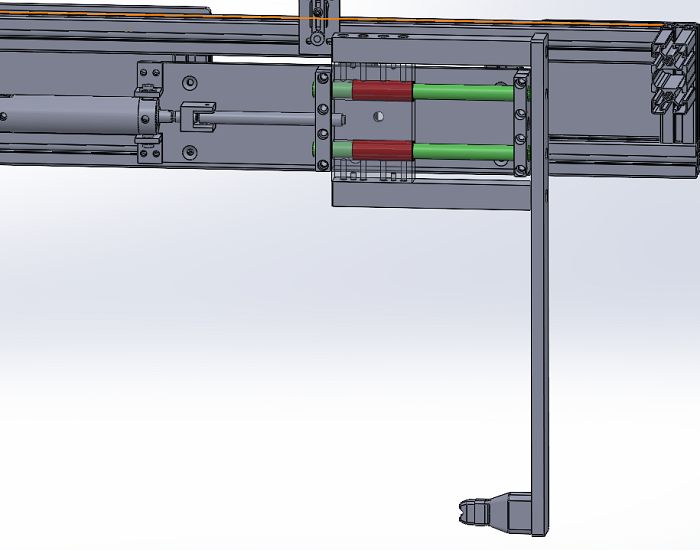

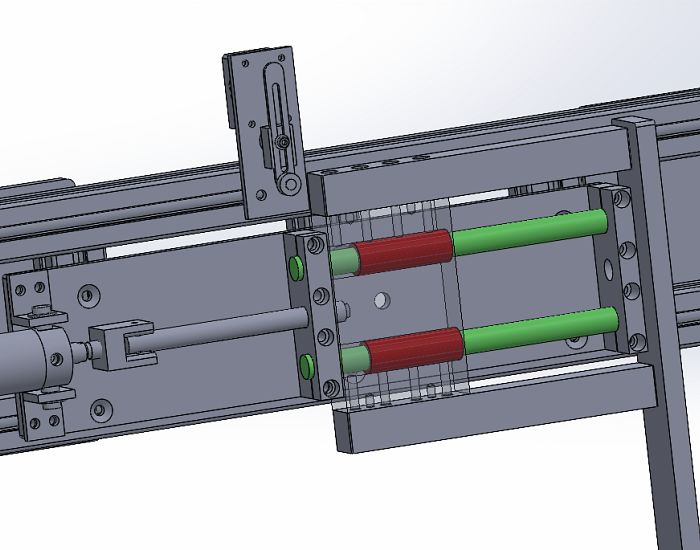

We designed and built linear guides to accurately position clamps in a lift assist.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Welche Anforderungen mussten die Lager erfüllen?

Maintenance free service life.

no grease or oils, cleanliness is imperative.

Manage >30kgf loads

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

J

R

A 180

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Bearings slide over Precision linear rail rods

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Bilder

Video

Video

Award ID: 1125 Company: Prodromus Sp. z o.o.

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 22:02:12

- Firma: Prodromus Sp. z o.o.

- Ansprechpartner: Pan Grzegorz Piątek

- E-Mail: gpiatek@prodromus.pl

- Anschrift: Ignacego Łukasiewicza, 1, 31-429 Kraków

- Telefon: 690904100

- Land: Polska

- Awareness: e-mailing

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Welche Anforderungen mussten die Lager erfüllen?

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Welche Lösungen aus der Polymer-Lagertechnik (wie zum Beispiel Gleitlager, Linearführungen,

3D-Druck-Teile, Teile aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

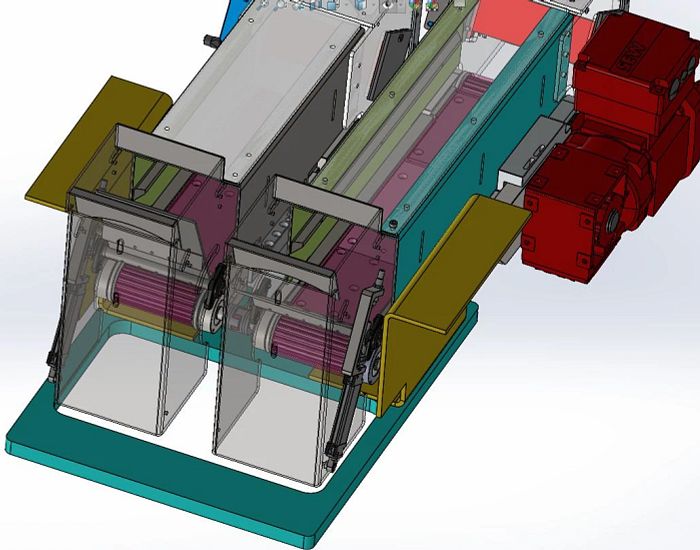

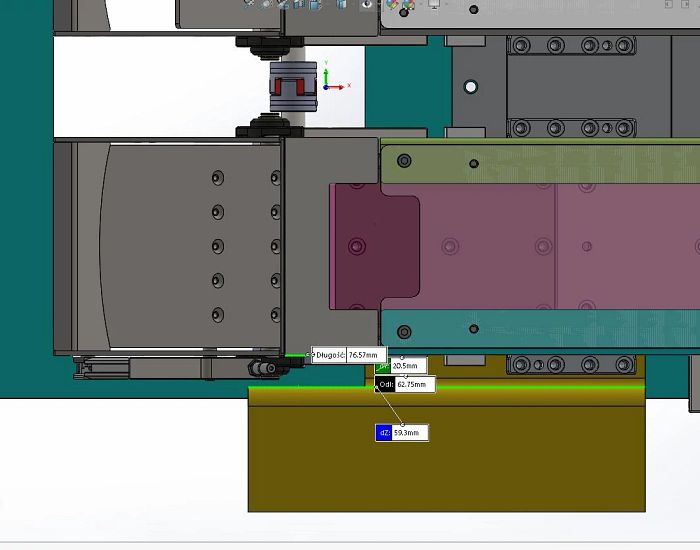

Bilder

Award ID: 1124 Company: PWr Solar Boat Team (Koło Naukowe Politechniki Wrocławskiej)

igu-award-adm | Februar 12, 2021

Allgemeine Informationen

- Datum: 2021-02-12 21:46:56

- Firma: PWr Solar Boat Team (Koło Naukowe Politechniki Wrocławskiej)

- Ansprechpartner: Pani Dominika Dewor

- E-Mail: pwrsolarboatteam@gmail.com

- Anschrift: Wybrzeże Wyspiańskiego 27, 50-370 Wrocław

- Telefon: 724980425

- Land: Polska

- Awareness: Colleagues