News form igus

Award ID: 1682 Company: SkillRoad

igu-award-adm | Februar 11, 2023

Allgemeine Informationen

- Datum: 2023-02-11 20:32:01

- Firma: SkillRoad

- Ansprechpartner: Mr irakli Datatashvili

- E-Mail: Erekledata@gmail.com

- Anschrift: Near Oranienburger 65, 10117 berlin

- Telefon: +18573918533

- Land: United States of America

- Awareness: Search engines

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

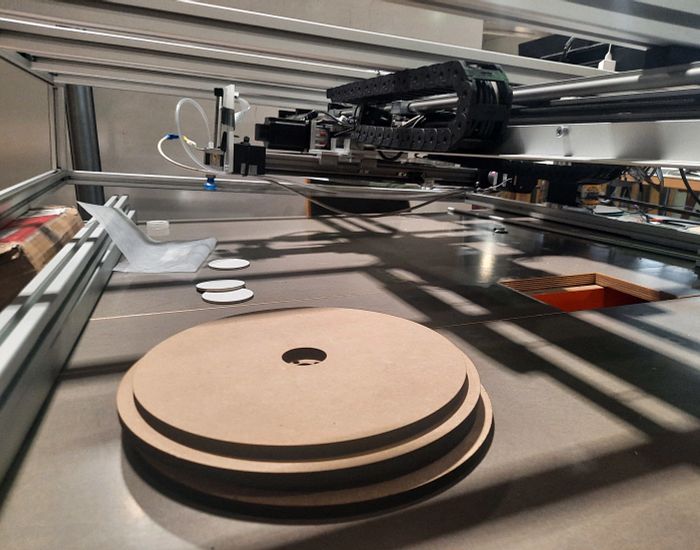

We introduce a multi-functional mushroom harvesting machine for aluminum shelving farms. The machine helps farmers to harvest and grow the yield of their crop by using cutting-edge AI technology. AI and smart software allows us to have the advantage to see and harvest “as humans” – but for better, faster, and longer hours. With the invention on board, mushroom harvesting is more accurate, more consistent, more analyzed, and picked at superhuman speeds. Software can look at different phenological stages, as well as measure and count mushroom size, and volume (can choose specific size only or in a predefined range) to give actionable insights and information to predictive yield estimates & harvests for mushrooms throughout the growing season. When operating as a “digital implement” in-field autonomy for automatic real-time harvesting the farm goes on a digital level.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Food compatible area, fmachine faces Moisture. Had to overcome food compatibility, we used plastic from igus to have machines without oil

Welche Anforderungen mussten die Lager erfüllen?

Work without oil lubrication. Using plastic bearings makes machin work with food with linear actuators doing the job

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Use food compatible lubricant, that’s very rare and not realistic

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

linear plain bearings, linear guides for linear actuators

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Money? (please specify an amount) 50000 Lubricant/grease? (e.g. saved litres of lubricant/grease) 100 Other resources?

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Quite normal, talked one of the providers and visited the place in Kolon several times. Got introduction in the exhibition area with professional advices

Bilder

Award ID: 1681 Company: ZPUE

igu-award-adm | Februar 11, 2023

Allgemeine Informationen

- Datum: 2023-02-11 06:47:23

- Firma: ZPUE

- Ansprechpartner: Pan Łukasz Krzyżanowski

- E-Mail: lukasz.krzyzanowski@zpue.pl

- Anschrift: Kościuszki 22, 29-145 Secemin

- Telefon: 694316749

- Land: Polska

- Awareness: e-mailing

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

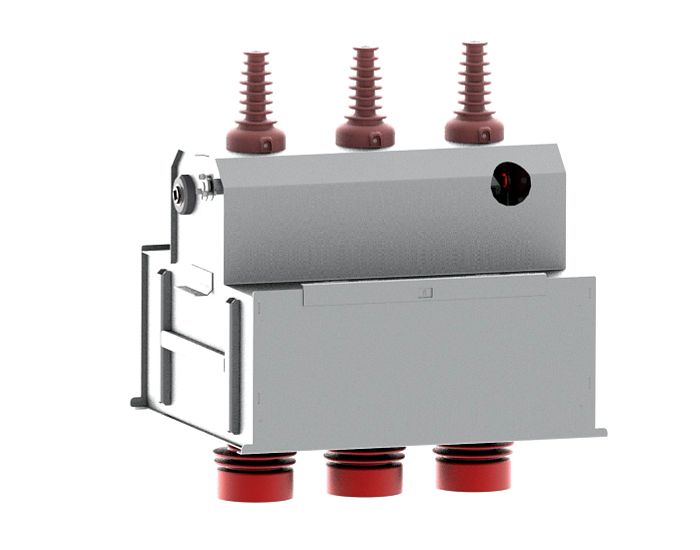

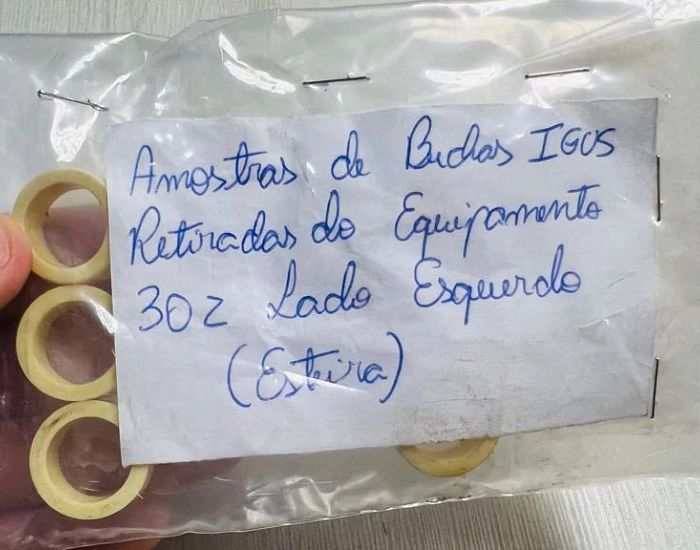

The device in which I used the greaseless Igus bushing is a three-phase medium-voltage disconnector in SF6 gas insulation. The bushing used acts as a bearing for the disconnector shaft that controls the disconnector contacts.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

The bushing operates in a hermetically sealed disconnector tank filled with pure SF6 gas. The biggest challenge was to ensure proper shaft bearing for the life of the device, bearing in mind that service would never have access to the bushing because the tank is hermetically sealed from the time it is installed in the tank until the end of the products life.

Welche Anforderungen mussten die Lager erfüllen?

The bearing had to be completely maintenance-free and withstand loads from a shaft rotating at 45 degrees with high angular accelerations.

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Nitrided steel bushing, ball bearing.

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

Plain bearings

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Costs? min. 50% compared to steel bushings Grease? (e.g., liters of grease saved) 20 kg/year Other resources? Reduced assembly time

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

I work with an Igus sales representative who provides advice, quick access to samples of various solutions, and quick quotes.

Bilder

Award ID: 1680 Company: Heineken Brasil

igu-award-adm | Februar 11, 2023

Allgemeine Informationen

- Datum: 2023-02-11 02:45:33

- Firma: Heineken Brasil

- Ansprechpartner: Sr. Gustavo Okubo Sabatin

- E-Mail: gustavo.sabatin@heineken.com.br

- Anschrift: Rod. SP-310, km. 270,6, Araraquara, SP, 14808 · ~1 km, 14800-656 Araraquara

- Telefon: 17997677693

- Land: Brasil

- Awareness: E-Mailing

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

In the long neck bottle filling process there is an equipment that makes the cleaning of the bottle (Rinser) and to keep the bottle in the desired position there is a component called: Rinser Follower, which is a part that slides under a circular axis and is lubricated by water. The application was to replace the original Rinser follower material with a self-lubricating Igus material, thus drastically reducing water consumption, cost and also the suppliers lead-time, since the component is printed with Iglidur 150 White filament.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

As the component slides on a circular shaft, the material experiences high-speed friction during use. Thats why water is needed for lubrication. Seeing the significant water consumption, we had the idea of using a material that was self-lubricating, and then came the solution of making the Rinser Follower with Igus material. At first, we had difficulty with the design of the material and the print settings (fill, number of walls, wall thickness, top thickness, etc). After several tests, we arrived at an ideal model and tested a unit on the machine which met our expectations.

Welche Anforderungen mussten die Lager erfüllen?

To be a material that could slide freely and unimpeded under the circular axis. Be able to remain in use for 6 months in the machine without presenting wear that would cause it to break.

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Before the current solution. The use of other materials was considered but did not meet expectations since these other materials had worn out before the original material. We also considered machining the material by purchasing IGUS billet, which met expectations but at a high cost. Finally we arrived at the current solution of printing the part using Iglidur150 filament.

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

A sliding part printed on a 3D printer with the filament-shaped polymer Iglidur150 was used

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Cost? (please specify a value) 6184,80 Other resources? Water

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Yes, we received them through visits from the technician in charge of the unit, who brought Igus novelties as well as proposed solutions for the use of self-lubricating materials.

Bilder

Award ID: 1679 Company: HEINEKEN BRASIL

igu-award-adm | Februar 11, 2023

Allgemeine Informationen

- Datum: 2023-02-11 01:44:43

- Firma: HEINEKEN BRASIL

- Ansprechpartner: Sr. VINICIUS ALMEIDA

- E-Mail: vinicius.silva7@heineken.com.br

- Anschrift: Rodovia WASHINGTON LUIZ SP 310,S/N – Km 270, 14808-080 ARARAQUARA

- Telefon: (16) 99613-4621

- Land: Brasil

- Awareness: E-Mailing

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

The project is based on the application of IGUS material in conjunction with the 3D printer present in the factory. Through the IGUS filament some "talisks" used in the Can Line Packer were printed, these talisks act as a transfer transport so that the cans enter the package smoothly through a side pusher. In other words, the slat material needs to withstand the working pressure and ensure that the cans "slide" during transfer, a task successfully performed by the IGUS filament.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

The project is currently exposed to a high workload, being used on equipment that runs 24 hours a day, every day of the week. Besides the constant movement of the chain and the friction with the cans, the project is also exposed to can bursting (contact with beer), to chemicals used by the operation to clean the equipment, and to pieces of metal from crushed or damaged cans.

Welche Anforderungen mussten die Lager erfüllen?

In the first step, it was necessary to study how much filling would be required during printing, and what would be the best position to print from. Initial tests related to filling and printing position resulted in the material breaking when placed on the test specimen (test chain). Tests with other materials resulted in "warping" of the splint and consequently cans falling off during transfer.

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

With the failure of the first materials used to print the component, it was practically obvious that only the manufacturer could supply a quality part that met the working conditions without affecting the production performance. Finally, through other IGUS applications at the plant, the idea arose to purchase the filament and start testing with IGUS GLIDURL 150 filament. Although the first prints did not generate efficient results, at the end of the studies an ideal print configuration was found for the filament and work application.

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

In the project only IGLIDUR150 filament was used, which had already been used for another application in the factory and proved to be very efficient and practical.

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Cost? (please specify a value) $250.00 Other features? Lifetime and print time.

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

The entire project was an internal initiative of the plants maintenance team, requiring only the supply of the filament by IGUS.

Bilder

Award ID: 1678 Company: Unitec

igu-award-adm | Februar 10, 2023

Allgemeine Informationen

- Datum: 2023-02-10 22:25:32

- Firma: Unitec

- Ansprechpartner: Sr. Antonio Antonio

- E-Mail: antonio.marcos.correa@hotmail.com

- Anschrift: Brasil, 6330000 sao paulo

- Telefon: 11995352173

- Land: Brasil

- Awareness: Other

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

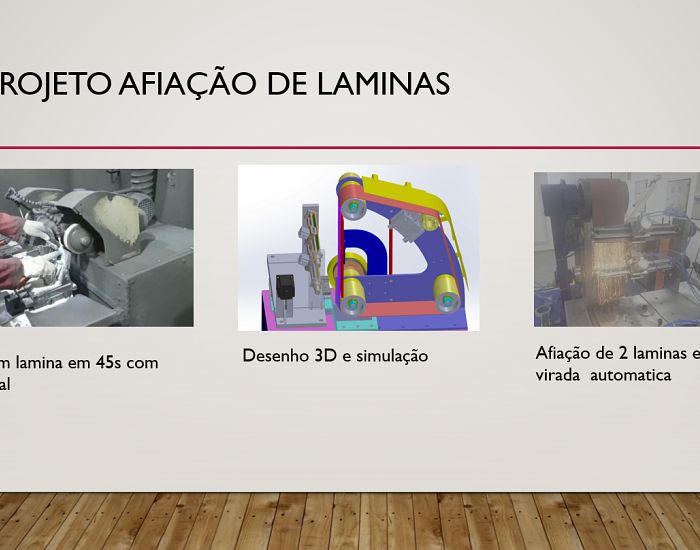

Sharpening of brushcutter blades

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Environment exposed to abrasive dust, lots of dirt. To develop equipment that would produce less noise and dust and increase productivity while maintaining quality.

Welche Anforderungen mussten die Lager erfüllen?

Increased productivity Quality improvement

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Changing the grit size

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

We use igus

1-buckets on a pulley

2-guides

3-patins

4-D1

5-Step motor with encoder

1-buckets on a pulley

2-guides

3-patins

4-D1

5-Step motor with encoder

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Cost? (please specify a value) 10,000.00

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Yes, The consultant participated in the project from the beginning and in the configuration at the time of assembly

Bilder

Award ID: 1677 Company: Mizarstvo Štolfa

igu-award-adm | Februar 10, 2023

Allgemeine Informationen

- Datum: 2023-02-10 22:17:42

- Firma: Mizarstvo Štolfa

- Ansprechpartner: Mr Jernej Frangež

- E-Mail: jernej.frangez1@student.um.si

- Anschrift: Ul. Borisa Winterja 5, 2310 Slovenska Bistrica

- Telefon: 38651620366

- Land: Slovenija

- Awareness: Colleagues

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

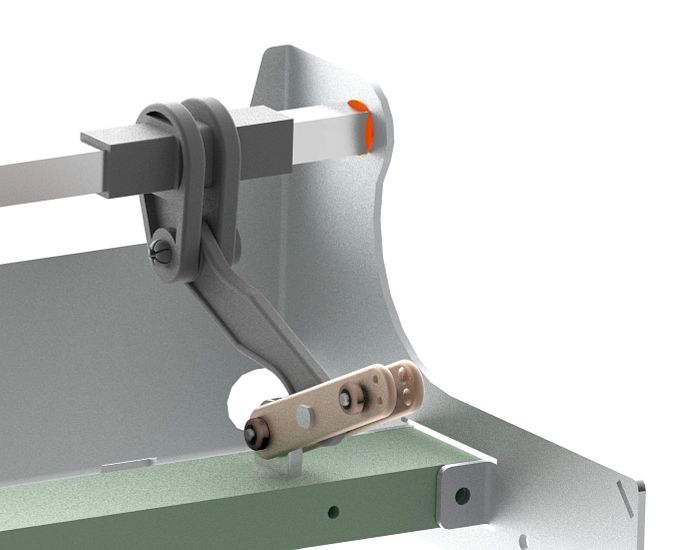

The project function is designed to open and close furniture parts remotely, like a stair, drawers, doors, lift speakers out of furniture, etc.

Application is used in smaller spaces where it will disrupt waking around. Those places are small apartments, boats, basements, tight halls, and much more. The goal was an adaptive platform which can be easily scaled for final purposes.

Application is used in smaller spaces where it will disrupt waking around. Those places are small apartments, boats, basements, tight halls, and much more. The goal was an adaptive platform which can be easily scaled for final purposes.

The presented application is used for remotely opening and closing stairs in a small apartment.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Operating condition is in the room temperature range and lower to around five degrees celsius for basements, with a higher humidity level. It should be silent, maintenance-free and easily adaptive to the used spindle's requirement size and outer diameter.

Welche Anforderungen mussten die Lager erfüllen?

Ensures spindle seating with low friction, maintenance-free, affordable price and long life.

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Ball bearing or custom made teflon parts

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

Iglidur J sleeve bearing with flange,

Drylin trapezoidal lead screw,

Dryspin flange lead screw nut,

Drylin trapezoidal lead screw,

Dryspin flange lead screw nut,

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Money? (please specify an amount) 200€ Lubricant/grease? (e.g. saved litres of lubricant/grease) a lot CO2? (e.g. weight saved in kilograms/grams) many Other resources? metal waste from milling

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Well, with the representative office in Slovenia.

Bilder

Video

Award ID: 1676 Company: Noordung d.o.o.

igu-award-adm | Februar 10, 2023

Allgemeine Informationen

- Datum: 2023-02-10 21:51:02

- Firma: Noordung d.o.o.

- Ansprechpartner: Mr Klemen Cepirlo

- E-Mail: klemen@noordung.com

- Anschrift: Skapinova ulica 2A, 1000 Ljubljana

- Telefon: 38682009931

- Land: Slovenija

- Awareness: E-Mailing

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

The Noordung bicycle is an electric bike of the highest class and addresses the challenge of cycling in an urban environment. It approaches these with a commitment to perfection in design, quality and flawless user experience. The heart of the bike is located in a smart multifunctional device called Boombox, which measures the level of air pollution and offers entertainment with the possibility of playing high-definition music.

Noordung team developed many components instead of buying them from the market—for example, frame, handlebar, fork, battery enclosure, etc. One of those is also the mechanism for the kickstand, which is completely integrated into the frame. And the following mechanism is rotating on Igus plain bearings.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

Operating conditions are external conditions ranging between all four seasons. During a ride, bearings can be exposed to dirt, dust, water, and grime against which they need to cope.

Welche Anforderungen mussten die Lager erfüllen?

Bearings have to fit in a small space, be resistant to the conditions described in the previous answer, not break under the load to which they are exposed, and last but not least, have a long lifespan.

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Because of the limited space, plain bearings were the only option. We initially opted for the Igus because of the broad range of dimensions and material options. You can get something for each application.

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

We use one stock version of plain bearing and one 3D-printed plain bearing for our application.

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Yes. A local Igus partner suggested a suitable material for the application and helped us with the 3D printing service.

Bilder

Video

Award ID: 1675 Company: Combi Packaging Systems

igu-award-adm | Februar 10, 2023

Allgemeine Informationen

- Datum: 2023-02-10 21:19:09

- Firma: Combi Packaging Systems

- Ansprechpartner: Mr Jacob Schurr

- E-Mail: jschurr@combi.com

- Anschrift: 6299 Dressler Rd, 44720 North Canton

- Telefon: 4126946807

- Land: United States of America

- Awareness: Other

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

This is what we call and SPP. It is a Servo Pick and Place machine. This machine is designed to erect a cardboard box, and load it with a customers specific product. Our SPP is utilized in manufacturing environments

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

The operating conditions at the users end site are typically clean and shouldn't pose any issues.

The major challenges we have to overcome are designing the machine to work with the customers products and sometimes having interchangeable parts that can accommodate different products.

Welche Anforderungen mussten die Lager erfüllen?

We did not use IGUS bearings in this machine

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

We did not use IGUS bearings in this machine

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

We use linear plane bearings and linear guides to my knowledge

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Other resources? Service time, because of us utilizing these service is not needed often

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Igus has always supplied us with parts, utilization of them has always been fast, efficient, and effective.

Video

Award ID: 1673 Company: Torfresma

igu-award-adm | Februar 10, 2023

Allgemeine Informationen

- Datum: 2023-02-10 19:48:23

- Firma: Torfresma

- Ansprechpartner: Sr. Rafael Sebben

- E-Mail: marketing@torfresma.com

- Anschrift: Rua Arno Erich schwambach, Rafael Sebben São Miguel do Oeste

- Telefon: +55 49991687080

- Land: Brasil

- Awareness: E-Mailing

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung? Wo wird Ihre Anwendung eingesetzt?

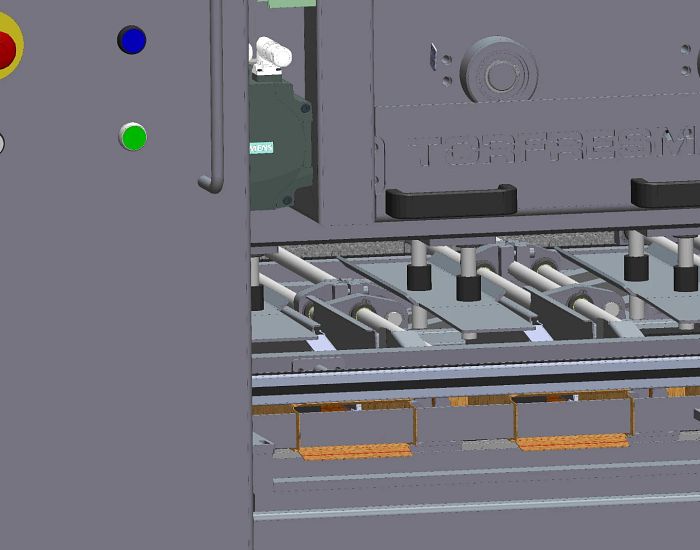

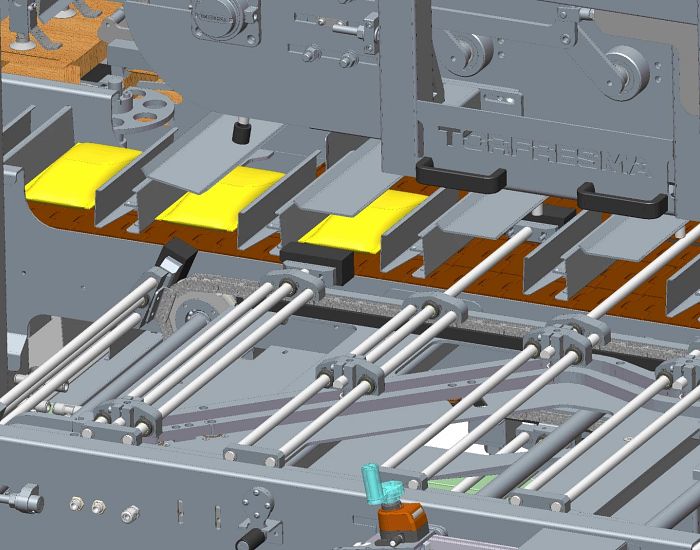

The Project is an Automatic Cartoner with a cam-driven cartoning system. The function is to push the product coming from the primary packaging into the cartridge. It is applied in a cold storage plant that produces chicken stuffed products.

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen?

The equipment is located in a cooled dry area, exposed to local dust and residues generated by wear and tear of the cardboard. The biggest obstacle was accommodating the product, since the package is composed of several small empanadas.

Welche Anforderungen mussten die Lager erfüllen?

The bushings and sliding shafts had to guarantee a safe, non-locking movement that would meet the line speed.

Welche alternativen Lösungen für die Lagerstellen kamen in Betracht?

Initially it was considered internal manufacturing of the components, we would do with bronze machined bushings and polished stainless steel shafts.

Welche Produkte aus der Polymer-Lagertechnik (wie z.B. Gleitlager, Lineargleitlager, Linearführungen,

3D-gedruckte Gleitlager, Gleitlager aus Halbzeugen, Steh-, Flansch- und/oder Gelenklager) setzen Sie ein?*

Linear slide bushings model RJUM-01-16 and precision shafts model DRYLIN AWMP-16 were used

inwiefern sparen Sie oder der Endanwender durch Einsatz der genannten Produkte…

Cost? (please specify a value) R$100 per axle

Gab es eine Zusammenarbeit mit igus? Wenn ja, wie verlief diese?

Yes, during the development of the project there were some consultations with Igus consultants to define the best application.